CVD DLC Coating

(Diamond-Like-Carbon)

CVD Coating

CVD Coating

Coating Services

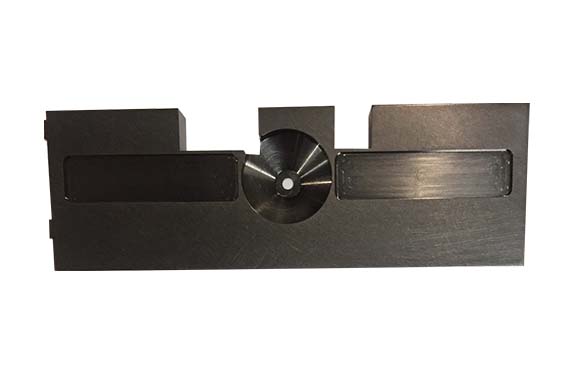

ACT provides a variety of advanced coating technologies including Chemical Vapor Deposition (CVD). CVD DLC is a chemical process that produces a thin high-quality coating using gases like Acethylene (C2H2). The C2H2 dissociates within a plasma into Hydrogen (H2) and Carbon (C). The Carbon is then used to grow a Diamond-Like-Carbon (DLC) coating.

This CVD coating provides a new and unique application to surface areas. Not only can the coating be applied to internal surface areas, but it can also be applied to intricate or complex shapes. The CVD process allows for the coating of narrow passageways such as valves and filters. It will also cover all areas including threads and blind holes, as well as both internal and external components.

This uniform solid coating can be used on a wide variety of materials including metal, ceramics, glass, and metal alloys. The application is used in many different industries including:

Aerospace

Automotive

Diesel

Marine

Medical devices

Tools

Marine

Medical devices

Tools

Request a Quote

Coating Advantages

Chemical Vapor Deposition can be used to produce high quality, high-performance solid materials.

Some of the benefits of applying this coatiang include:

- High thermal conductivity and heat transfer performance

Increased toughness and durability

Impact and crack resistance

Prevents oxidation

Resistant to wear

Resistant to abrasion and erosion

Resistant to aggressive and corrosive chemicals such as acids

Withstands harsh environments

Prevents fatigue

Extends the lifetime of the component, reducing down-time for repair

ACT is focused on a high-quality coating application to optimize the performance and efficiency of the component, allowing for increased uptime and profitability. The CVD coating provides greater protection to the component allowing it to withstand exposure to low and high temperatures as well as acting as a barrier to corrosion and wear. The extended tool life will allow you to spend less time and money on tool changes or repairs.

CVD coatings are known as being an environmentally friendly durable surface.

WHO WE ARE

Advanced Coating Technologies (ACT) is located in Valencia, California and we are SoCal’s leading service provider of advanced surface coatings. We use the latest state-of-the-art European coating technology. We have a great team of experienced coating staff and scientists that can make a difference in providing you with quality coating solutions.

Dr. Andreas Schuetze, our Vice President of Technology, has over 30+ years of experience in the area of advanced thin film coatings. ACT has also invested a large amount of time and resources in our facility to provide you with superior technologies. Our dedicated scientist and the team will work with you. Our goal is to provide you with innovative solutions and quality service to ensure your coating needs are met.

You Make It First, We Make It Last!

Why Advanced Coating Technologies

PVD and DLC Coating Capabilities

Extensive Material and Coating Testing

Industry-Leading Research and Development Team

Enhanced Quality Control & Quick Turnaround

Ph. D. Scientist on staff

Federal Firearms License

ISO 9001 & AS9100 Certified

How To Contact Us

How To Contact Us